NIVOCONT K level switches, based on the conductivity principle, can be applied to liquids with conductivity higher than 10-5 S/cm.

For detecting the level, probes are immersed into the tank. These probes (and the tank wall if conductive) serve as contacts of an electric circuit.

Probes can be of single or multiple rod versions. A maximum of 4 probe rods can fit in the multiple probe socket with an additional reference probe if tank wall is not conductive.

The probe length should be in accordance with the level to be detected. When the liquid level reaches the probe, it will create a short-circuit and the output relay will be activated. The device senses the conductivity difference between the probes and the reference probe. The KLP separators should be used at every 0.5 m to provide suitable distance between the probes.

Main Features:

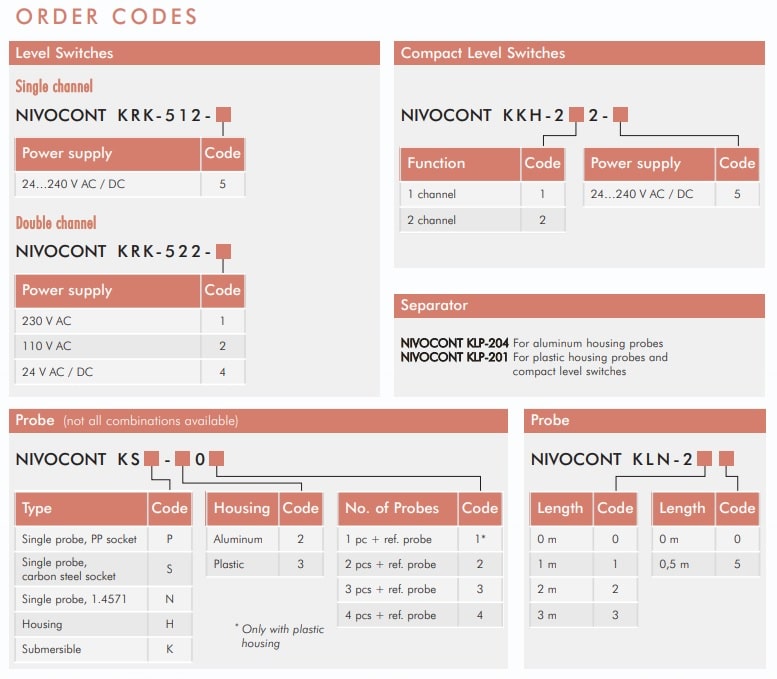

Level switches

KRK-512

- Level switching

- Filling-emptying control

- Selectable NO/NC relay function

- Adjustable sensitivity

- Adjustable delay ON and delay OFF time

- Delay time indication

- AC/DC versions

KRK-622

- The following functions can

be selected:

– Monitoring of 2 independent levels in 2 tanks

– Monitoring of 2 independent levels in 1 tanks

– Pumping from one tank to another - DIP switch selection on the front panel (8 functions)

- Adjustable probe sensitivity (for each probe separately)

- Adjustable relay switching delay (for each probe separately)

- AC/DC versions

Compact level switches

KKH-2_2

- Probe and relay in one unit

- 1 or 2 incorporated KRK-512 electronics

- 1 or 2 independent relay outputs for pump control or differential level switching

- Selectable NO/NC relay function

- Adjustable sensitivity

- Adjustable delay ON and delay OFF time

- Delay time indication

- AC/DC versions