Description:

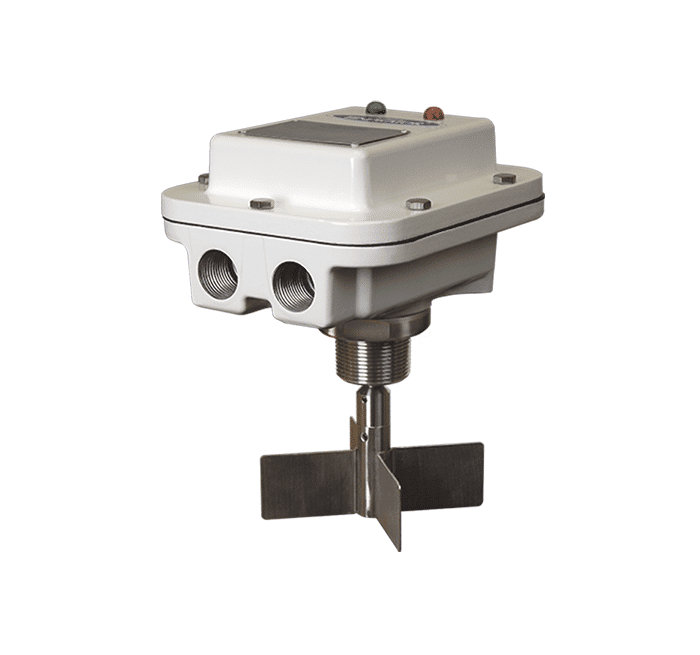

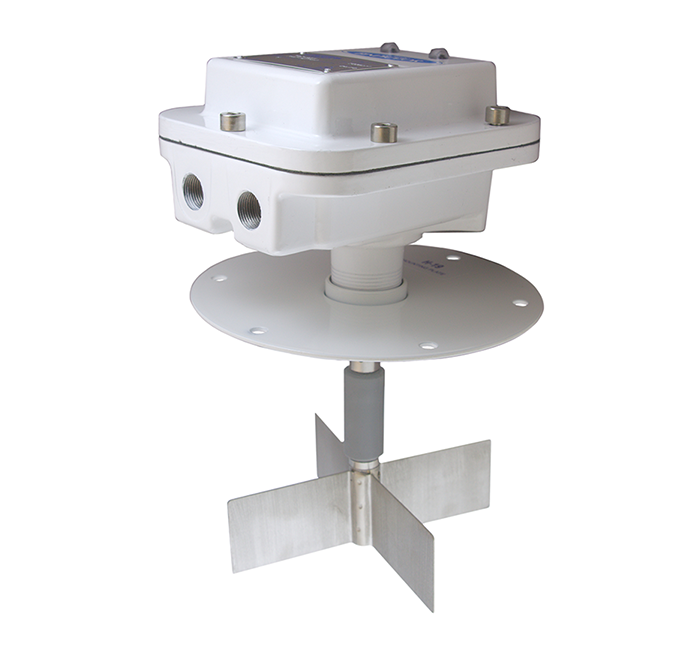

The Roto-Bin-Dicator® PRO is a paddlewheel type level device that outperforms others in its class. This simple device monitors the level of dry bulk material and indicates when there has been a change. The fail-safe PRO model is unique in that it comes standard with functional diagnostics that detect a unit fault even when the paddle is buried in material; unlike other paddlewheel devices.

The PRO provides added reliability by employing redundant methods of detection. These methods monitor shaft rotation as well as motor behavior, making it more reliable with regards to not missing a reading or creating a false positive.

Actively protecting your inventory

The Roto-Bin-Dicator PRO model is a genuine fail-safe level switch, performing self-diagnostics while in and out of material to protect your dry bulk investments.

Detect faults in and out of material

As a genuine fail-safe sensor, Roto-Bin-Dicator PRO can perform complete self-diagnostics in and out of material. Other paddlewheel devices can only perform diagnostics when the paddle is not in material. PRO provides undeniable confidence that the unit is functioning.

Technology: Paddlewheel

Applications: Universal, dry bulk point level detection with advanced features and diagnostics

Differentiate between faults

Diagnostics alone are not uncommon, but the ability to differentiate between faults is. Roto-Bin-Dicator PRO is the only paddlewheel level device in the dry bulk industry that can differentiate faults such as:

- Supply Voltage

- Motor Not Connected

- Electronics Temperature Range

- Motor Failure

- Gear train / Bearing Failure

- Electronics Failure

Greater range of dry bulk applications

Standard features include multiple sensitivity settings, universal power, time delay and motor pause allowing the same unit to be used in different locations and with a variety of dry bulk materials.

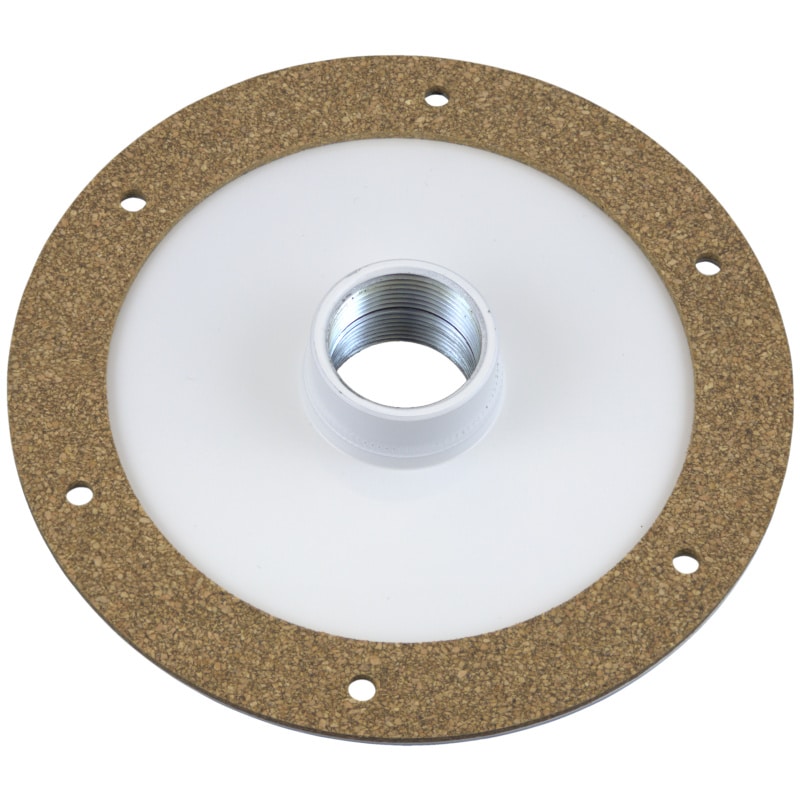

Variety of configurations & paddle options

Custom length pipe extensions and lags are available to extend Roto-Bin-Dicator PRO into a vessel or move its electronics away from high process temperatures. Extensive process fitting options allow the unit to be placed into new or existing fittings and seven paddle options cater to materials of varying densities.